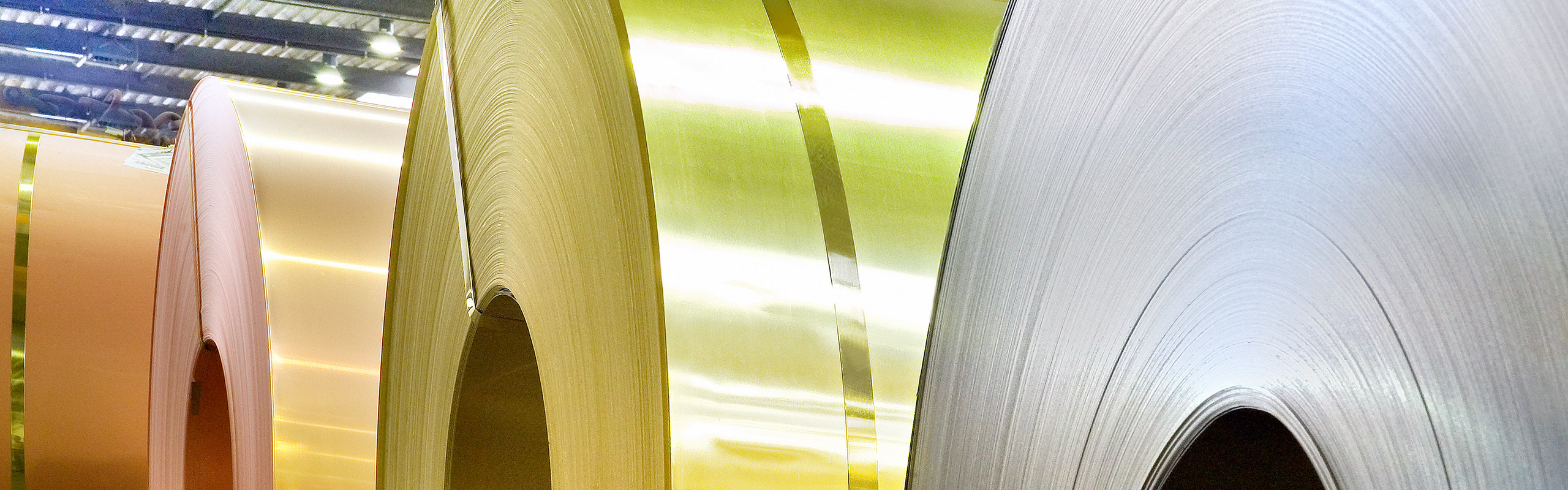

Product characteristics

- Economical further processing

- Excellent solderability

- Excellent formability, copper acts as lubricating agent

- Very good adhesion of copper layer during forming process

- Good corrosion and temperature resistance

- Extremely accurate measurement and quality tolerances of steel strip and copper layer

- Selective plating possible upon inquiry.

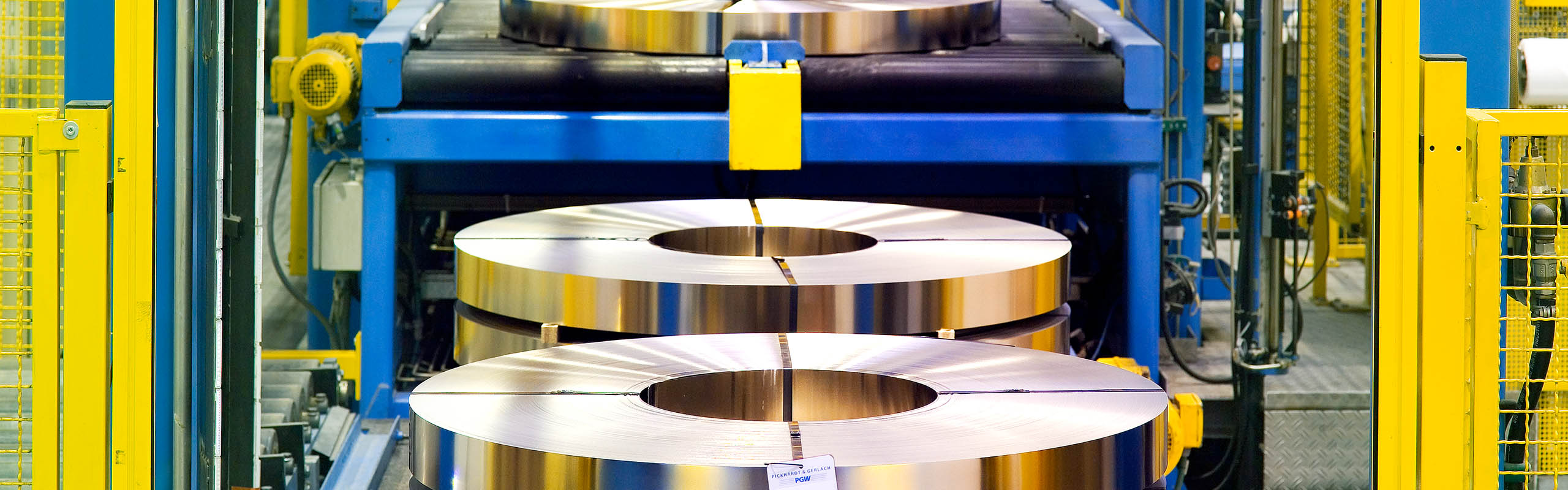

Range of products for steel strip electroplated with copper

| Grades | ||

|---|---|---|

| Designation | Processing states | |

| DC 01 | LC - C690 | |

| DC 03 | LC - C490 | |

| DC 04 | LC - C490 | |

| other grades upon inquiry | ||

| Surfaces The surface data stated refer to blank and unmodified strips |

||

|---|---|---|

| Surface types | Version | Roughness (Ra) μm |

| MA | RR, RM | 0,75 - 2,25 |

| MB | RL | < 0,60 |

| MC | RN | < 0,20 |

| Stone finish | 0,25 - 0,60 | |

| Thickness of layers | ||

|---|---|---|

| Thickness of layers 1 - 10μm each side |

| Dimensions | |||

|---|---|---|---|

| Thickness | Width | Coil weight | Inner diameter |

| 0,20 mm – 2,50 mm | 5 mm – 620 mm | max. 10 kg/mm strip width | 300 / 400 / 500 mm |

| Coils / Spools |

|---|

| one-layered wound up to 10 kg/mm strip width |

| multi-layered oscillated wound from a strip width of 5mm to 50mm in coil weights of up to 3.5to |

| Further surface finishing |

|---|

| polishing |

| clear varnishing |

| coating with pull-off foil |

| patterning |

| Standards | ||

|---|---|---|

| Dimension | Quality | |

| European standard 10140 | European standard 10139 | |